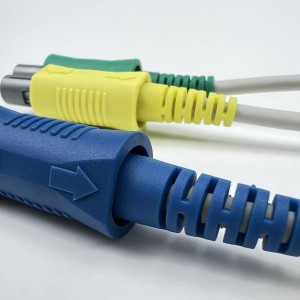

Customized/ODM/OEM create new connectors according to customers requirement and special connectors

Sample status: Available

Lead time: Within 1 week (In stock products).

How to buy: Send email to our customer service team : cs1@bexkom.com, we would reply you in 24hours.

Shipment term: By express delivery, door to door, normally 7~10days.

Any inquiries we are happy to reply, please send your questions and orders, thank you.

Product Details

As a special customized product, the needs of customers may have many kinds, and it may also be very strange and special requirements, but we believe that customers have their own considerations, maybe they need to achieve some special purposes, or do not want to use the standard products, or hope that new products have their own LOGO, etc. In short, our years of experience in connectors can allow us to carry out special designs for customers, including product design, product reliability assessment, material selection, component selection design or otherwise. First of all, we will communicate with customers patiently for many times to ensure that we fully understand the needs of customers, and then carry out the research and development of design drawings, product feasibility assessment, product development cycle estimation, product development cost estimation, including the signing of non-disclosure agreements, etc. , After reaching a complete agreement with the customer, based on our experience, we can quickly determine what kind of material, what kind of appearance and structure, and what kind of design can make the performance parameters of our products approach or reach Customers' requirements, that's why our development cycle usually only takes 4~6 weeks, or even faster, because we know that the market waits for no one, and time is money.

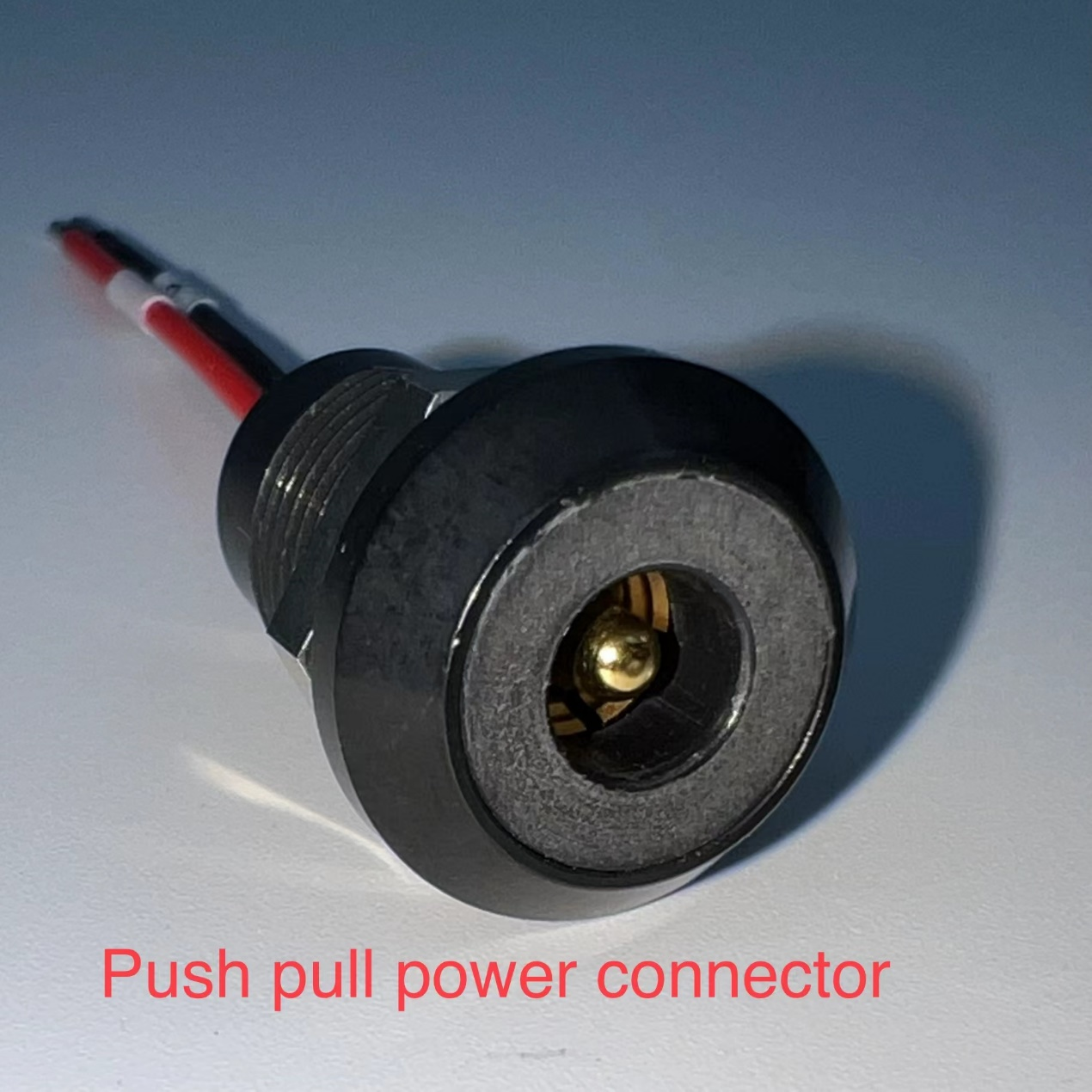

So far, we have customized many different types of products for customers, not only limited to push-pull self-locking connectors, our long-term partners such as mold, material and other suppliers can provide us with a lot of professional knowledge and help, we have always put suppliers As our close partners, they really help us a lot.

We customize more than 30 projects for our clients every year.

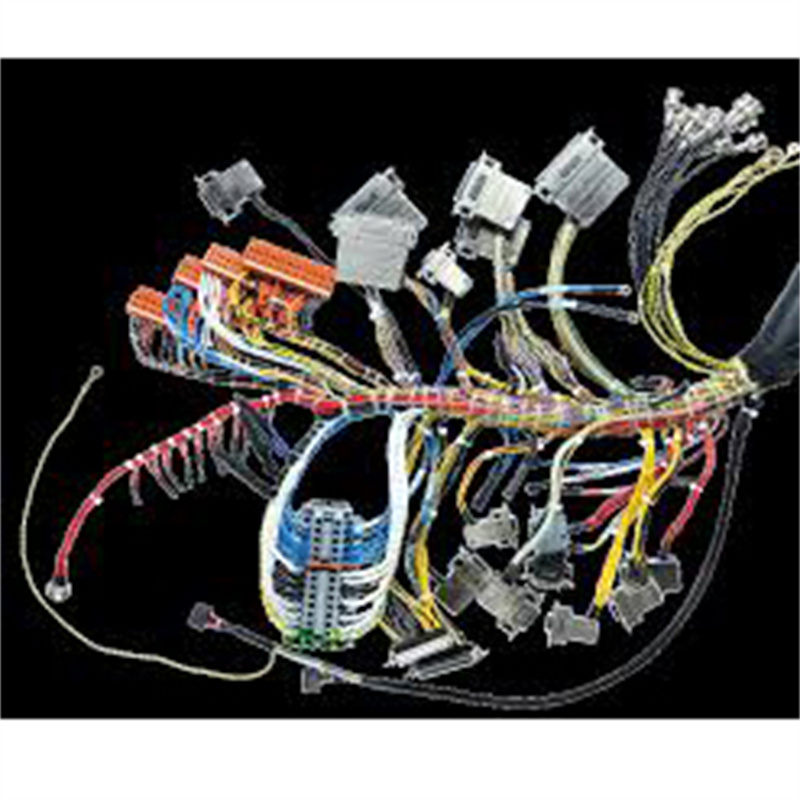

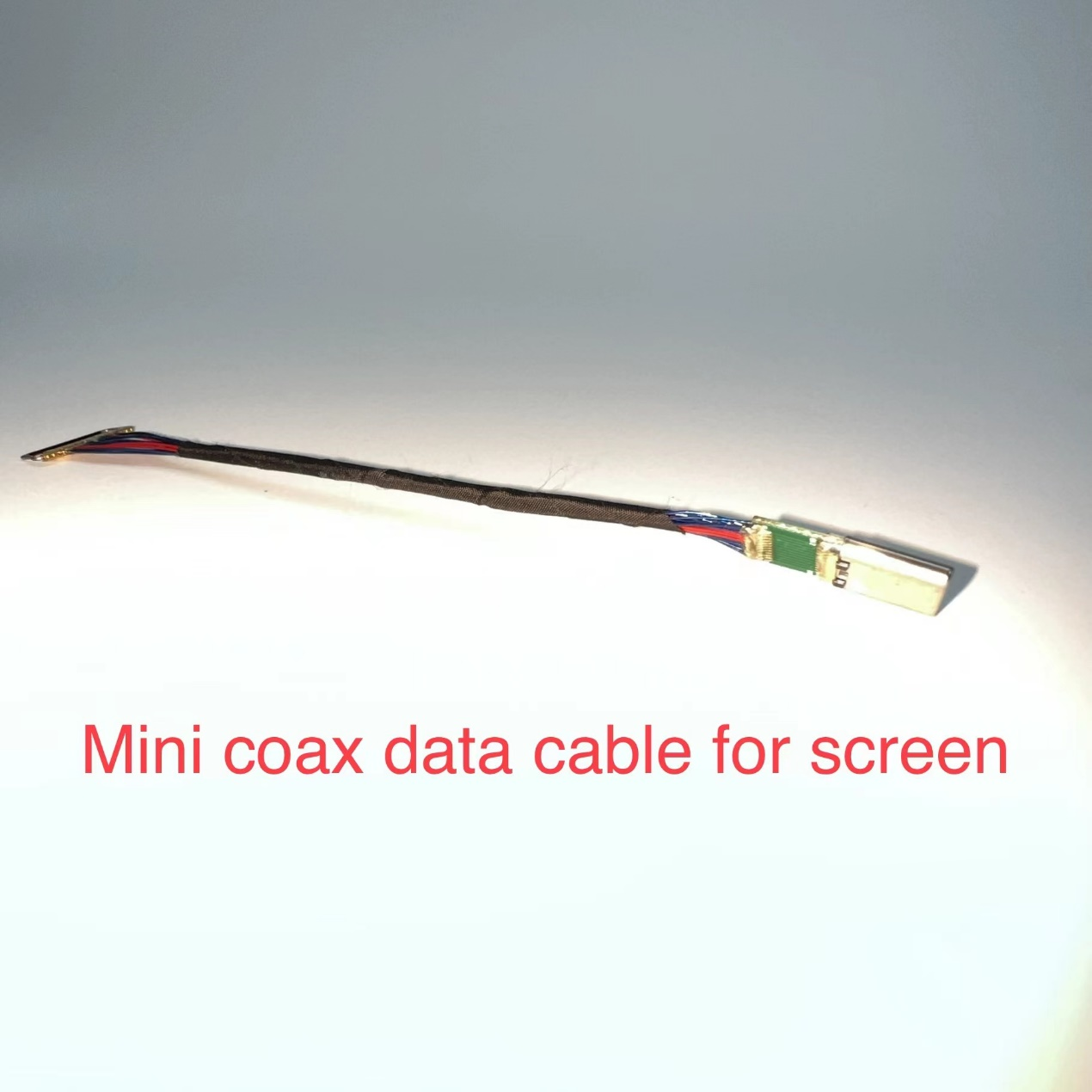

Our customized products include circular connectors, coaxial connectors, hybrid connectors, special cable assemblies, special material connectors and more.

Features

● 360 degree EMC shielding

● Contact number: 2~32

● Size:00,0,1,2,3,4(Hole size from 7.1 to 25.1mm)

● High density

● Mating cycles >5000

● >72Hours salt spray corrosion test

● 5 kinds of coding.

● Solder/crimp/PCB terminal available

● Shell material: brass chrome plated

● Contact material: brass gold plated

● Insulator: PPS/PEEK

● Temperature range:-55 ~ 250℃

● IP50 protection

Applications

Special customized products will not be limited to which industries as long as the customer's needs and ideas are in line with us. Whether it is outdoor equipment or indoor equipment, whether it is aviation industry or electronic consumption, whether it is special function or special material requirements, it can be achieved according to advanced design and advanced materials.

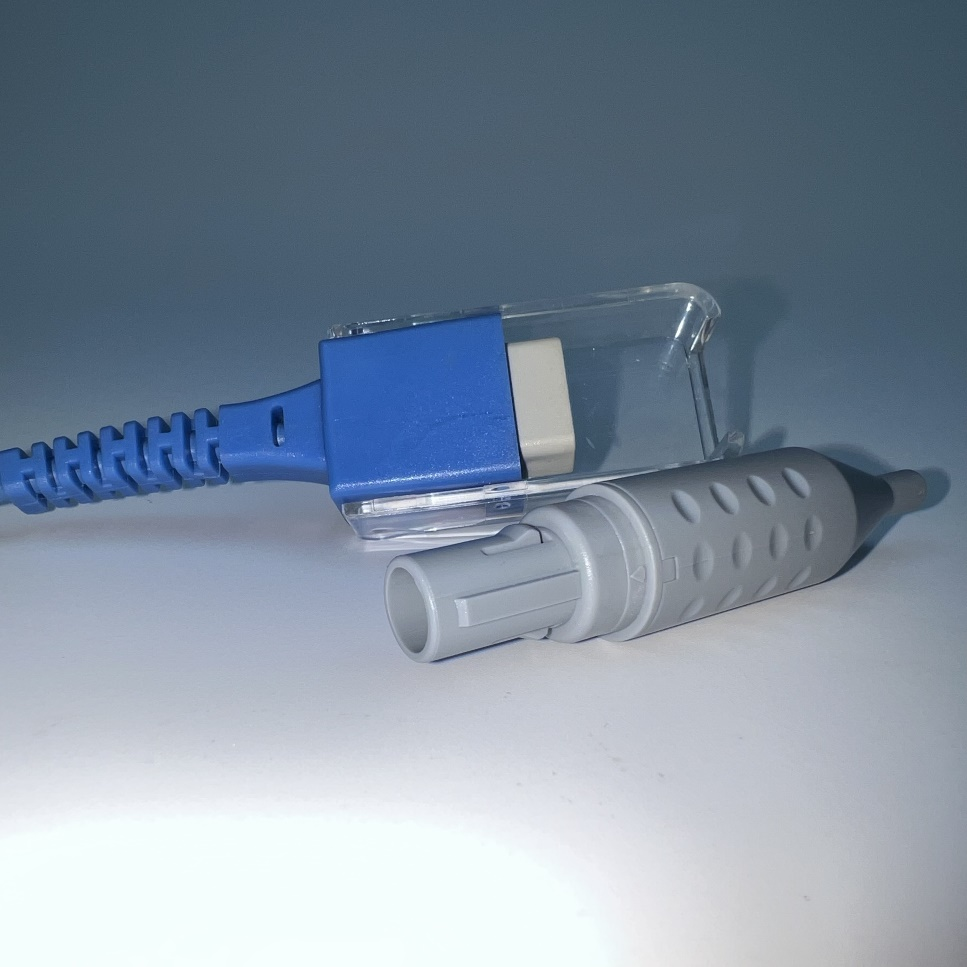

Endoscope

Aircraft power detection

Multifunctional multi-channel sense cable

Mechanical arm

Event broadcast equipment

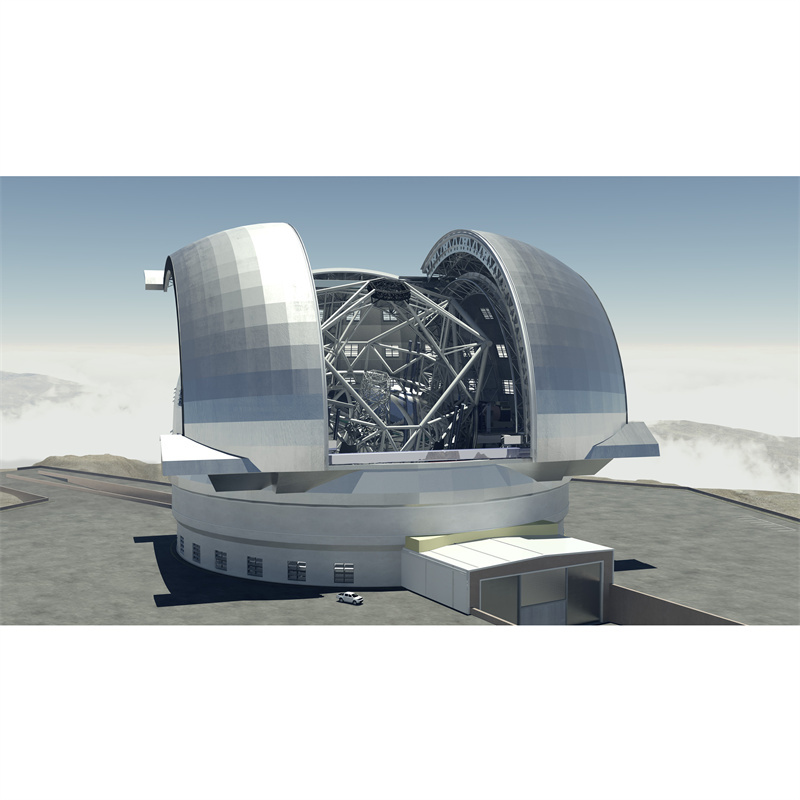

Astronomical observatory data transmission

Samples/Structures/Detail

Note: Only a few models and their drawings are listed here, if you need more information, please go to the download center to download our product manual or contact us.

| Series: | Customized | ||

| new connector according to customers requirment, OEM/ODM/Cable assembly/Special design | |||

| Shell material | Brass chrome plated | Lock style | All |

| Socket material | Brass gold plated | Shell size | All |

| Pin material | Brass gold plated | Contact number | 2~65 |

| Insulator | PPS/PEEK/PA66 | Termination area | AWG40~AWG14 |

| Shell color | Black, Silver | Termination style | Solder/PCB/Crimp |

| Mating cycles | >2000 | Produce technology | Turned/Stamp |

| Pin diameter | 0.5~8.0 mm | Coding number | 5 |

| Temperature range | ℃(-55~250) | Cable diameter | 1~22mm |

| Testing voltage | 0.5~1.9(KV) | Overmoulding available | Yes |

| Current Rated | 3~60(A) | Salt spray corrosion test | 96Hours |

| Humidity | 95% to 60℃ | Expiration date | 5 years |

| Resistance to vibration | 15g(10~2000Hz) | Guarantee period | 12 months |

| Shielding efficiency | >95db在10MHz | Certifications | Rohs/Reach/ISO9001/ISO13485/SGS |

| >75db在1GHz | Aplication | Military,testing,Equipment,handset/Medical | |

| Climatical category | 55/175/21 | Where used | Outdoor/indoor |

| Shock resistance | 6ms,100g | Customized service | Yes |

| Protection index | IP68/IP50 | Sample available | No |

(1) Can you produce according to samples? Yes, we can produce according to your samples or technical drawings. We can manufacture moulds and fixtures. (2) Will you infringe others’ patents? We take our brand and reputation very seriously. We have our own R&D and design, and we promise that we will not infringe any patents of others, and our legal advisors will intervene and evaluate products during product development. (3) What testing equipment do you have? We take product testing very seriously. We have our own complete set of testing equipment for connectors and cables, such as: constant temperature and humidity testing machine, plug-in life testing machine, waterproof testing machine, gas leakage testing machine, negative pressure testing machine, cable swing testing machine, impedance testing machine, continuity tester, high voltage tester, ROHs tester, coating thickness tester, tensile tester, salt spray tester, etc.

(4)What is your development client ranking?

Our current high-quality customers include Philips, GE, Mindray, Carlisle, Hytera, Hokai, Sunray, and other well-known domestic and foreign listed companies and famous brands.