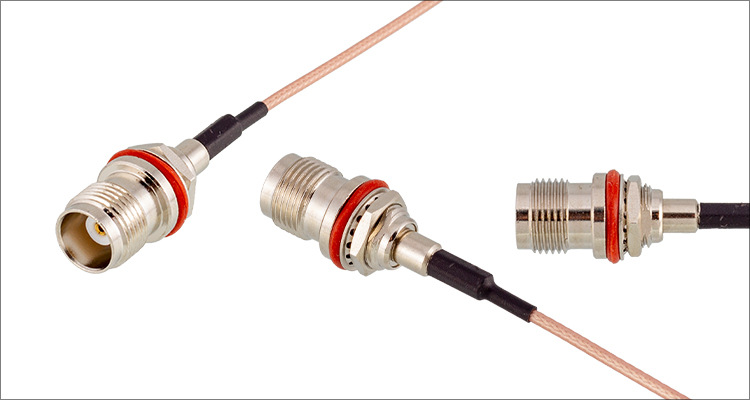

High Precision RF Coaxial Connector with coax cable

Sample status: Available

Lead time: Within 1 week (In stock products).

How to buy: Send email to our customer service team : cs1@bexkom.com, we would reply you in 24hours.

Shipment term: By express delivery, door to door, normally 7~10days.

Any inquiries we are happy to reply, please send your questions and orders, thank you.

Product Details

There are many coaxial products on the market, and they are uneven. Bexkom Coax series products mainly focus on high-end high-precision coaxial connectors, and have relatively strict requirements on their performance parameters. This series of products are required to have high precision, low impedance, low loss, high shock resistance, and standing wave ratio < 1.3. The transmission data is stable and the anti-interference ability is strong. At the same time, we are equally high on coaxial cables and their processing and testing processes. Coaxial connectors require that the contact body be plated with gold, the contact impedance of the coaxial cable is required to be very low, and the metal surface of the cable and the uniform wiring are not damaged during the cable processing. We recommend using the crimping process whenever possible and using very suitable and precision crimping tools. At the same time, we have developed a variety of wiring methods to enhance the coaxial shielding performance, which can make the signal transmission process free from external interference.

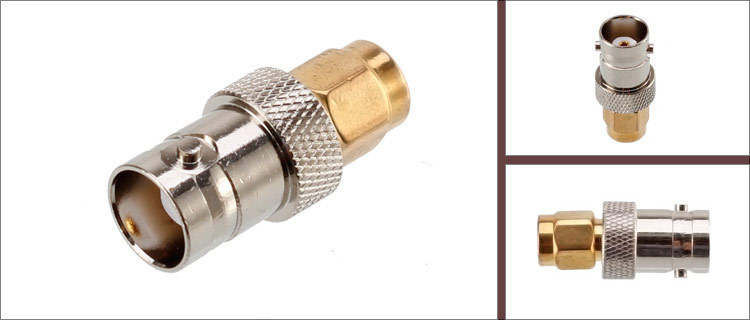

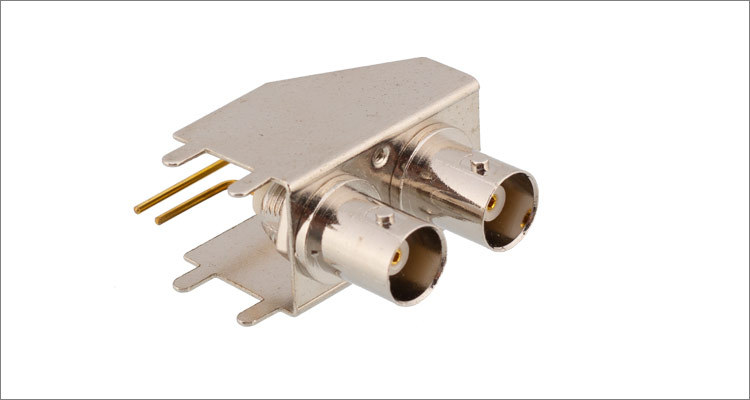

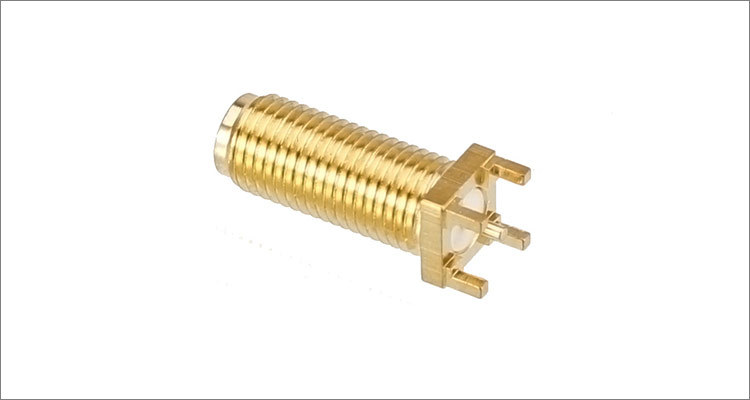

Our product series is complete, and commonly used products can basically be selected from our standard products. The smallest range from the SSMA/MMCX series on the printed circuit board to the BNC/UHF series commonly used in the external interface of large equipment, and the delivery time is short, and the basic delivery time is within 1~2 weeks.

On the basis of ensuring quality, we will try our best to use mass production to reduce costs.

Each coaxial cable is 100% tested for its key parameters after processing.

Some Exampl

Features

1.SWR<1.2~1.45

2.Style: BNC/TNC/N/UHF/SMB/SMB/SSMA/SSMB/MCX/MMCX/L5/SMC

3.Size:00,0,1,2

4.Characteristic impedance: 50/75 Ohm

5.Frequency range: 0~6GHz

6.Mating cycles >500

7.> 48Hours salt spray corrosion test

1.Solder/crimp/PCB terminal available

2.Shell material: brass nickel or gold plated

3.Contact material: brass gold plated

4.Insulator: TPFE

5.Temperature range:-55 ~ 2155

6.IP50/IP67 protection

7.Work voltage: 335 r.m.s

8.Insulation resistance: >1000MOhm

Applications

U series products are mainly used in the military industry, as well as some very precise devices that require small size of connectors, such as hand-held detectors.

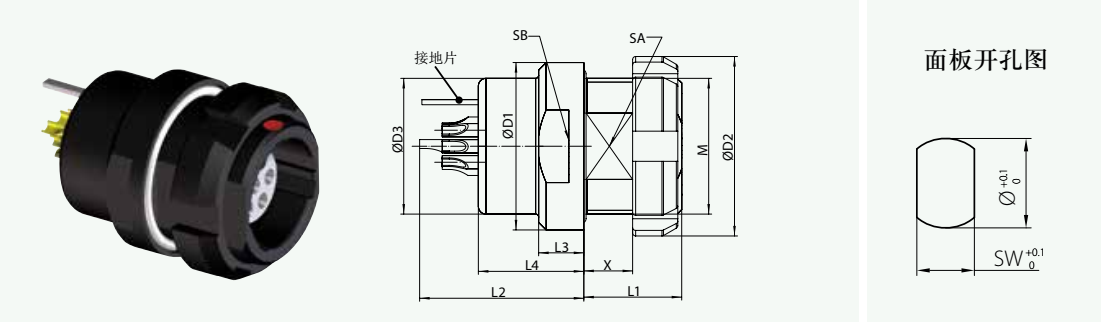

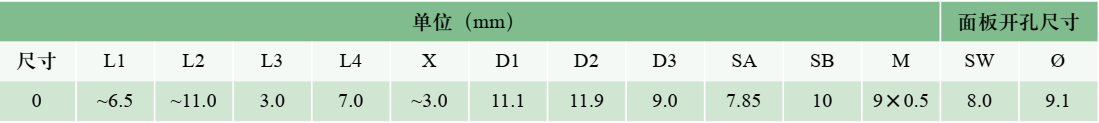

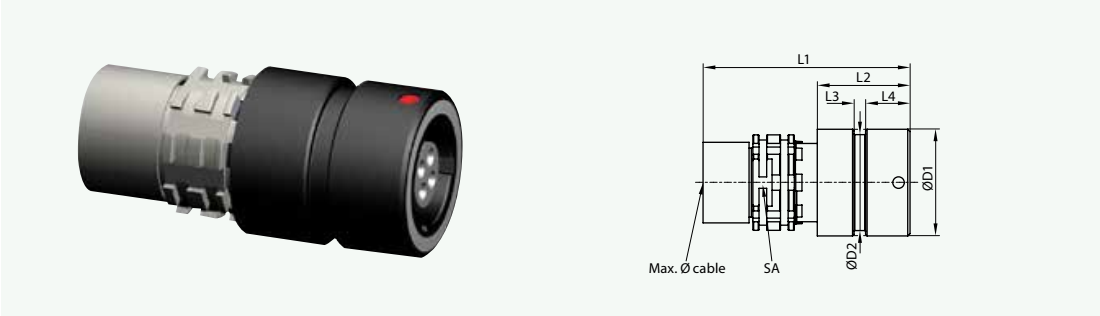

Samples/Structures/Detail

Note: Only a few models and their drawings are listed here, if you need more information, please go to the download center to download our product manual or contact us.

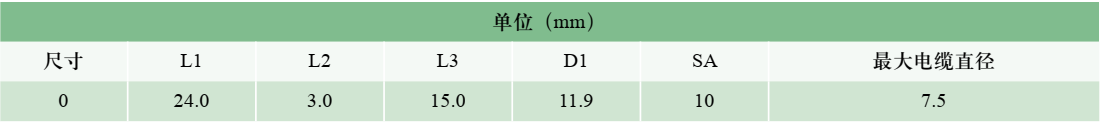

| Series: | U | ||

| IP68 waterproof,Metal circular,push pull lock, 360 degree EMC connector, High density | |||

| Shell material | Brass chrome plated | Lock style | Push pull |

| Socket material | Brass gold plated | Shell size | 00,0 |

| Pin material | Brass gold plated | Contact number | 2~13 |

| Insulator | PPS/PEEK | Termination area | AWG32~AWG16 |

| Shell color | Black, Silver | Termination style | Solder/PCB |

| Mating cycles | >5000 | Produce technology | Turned |

| Pin diameter | 0.5~2.0 mm | Coding number | 5 |

| Temperature range | ℃(-55~250) | Cable diameter | 1~6mm |

| Testing voltage | 0.5~1.6(KV) | Overmoulding available | Yes |

| Current Rated | 2~10(A) | Salt spray corrosion test | 96Hours |

| Humidity | 95% to 60℃ | Expiration date | 5 years |

| Resistance to vibration | 15g (10~2000Hz) | Guarantee period | 12 months |

| Shielding efficiency | >95db 在 10MHz | Certifications | Rohs/Reach/ISO9001/ISO13485/SGS |

| >75db 在 1GHz | Aplication | Military,testing,Equipment,handset | |

| Climatical category | 55/175/21 | Where used | Outdoor/indoor |

| Shock resistance | 6ms,100g | Customized service | Yes |

| Protection index | IP68 | Sample available | Yes |

(1) Can you provide samples for free? Yes, we can provide a small amount of test samples for free according to the project situation, but the freight needs to be borne by the customer. (2) What is your production process? 1. After the production department receives the assigned production order, the production plan will be arranged. 2. Relevant departments will conduct project review and evaluation as soon as possible to ensure that the production capacity meets customer requirements. 3. Check and confirm the BOM, if there no problem, then material distribution and production equipment debugging. 4. Prepare the corresponding operation documents and confirm by the engineering team. 5. The first sample is produced and confirmed. 6. Mass production. 7. Quality inspection. 8. Packing and storage. 9. Shipping.

(3) How long is your normal product lead time?

Usually 2-4 weeks

(4) Do you have a product MOQ? If yes, what is the minimum quantity? Each type of product will have some differences, generally 10pcs, you can consult our customer service staff for details. (5) What is the monthly output value of the product? Our company has a wide variety of products, and the normal monthly output of each product is about 50,000 sets.