New energy Series

Sample status: Available

Lead time: Within 1 week (In stock products).

How to buy: Send email to our customer service team : cs1@bexkom.com, we would reply you in 24hours.

Shipment term: By express delivery, door to door, normally 7~10days.

Any inquiries we are happy to reply, please send your questions and orders, thank you.

Product Details

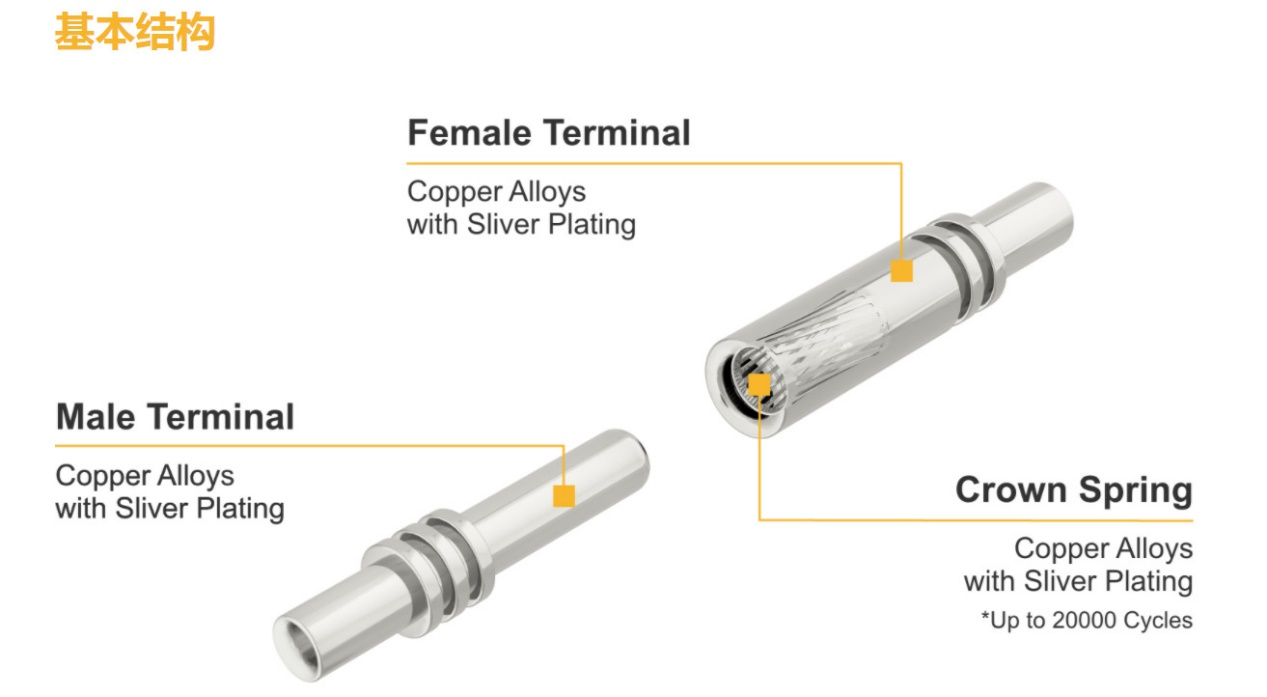

Bexkom new energy series connectors mainly use crown springs as core contacts. The crown spring is a mesh-shaped contact body made of flat beryllium copper material after weaving, which has the functions of increasing the contact area, increasing the transmission current, and increasing the shock resistance. The contact reliability of the parts has been greatly improved. The production and installation process of the crown spring is much more complicated than the ordinary pinhole, and it can reach the waterproof level of IP68 and the working current of up to 240A.

Bexkom new energy series connectors are mainly used in new energy vehicles, energy storage equipment, electromechanical equipment, locomotives, solar energy, wind energy, high voltage transmission equipment, high current transmission equipment and so on. Since each enterprise has different use occasions and use structures for new energy connectors, generally speaking, in addition to the contact body and standard cables, other parts such as shells, structures, and performance parameters are different, so customers require special The probability of customization is also relatively high.

We can design different types of connectors with different structures and different performances for customers according to their requirements.

Some Example

Features

1.Current rate: 1~240A

2.Contact number: 1~9

3.Work voltage: 1500V

4.Excellent shock resistance

5.Mating cycles >10000

6.>96Hours salt spray corrosion test

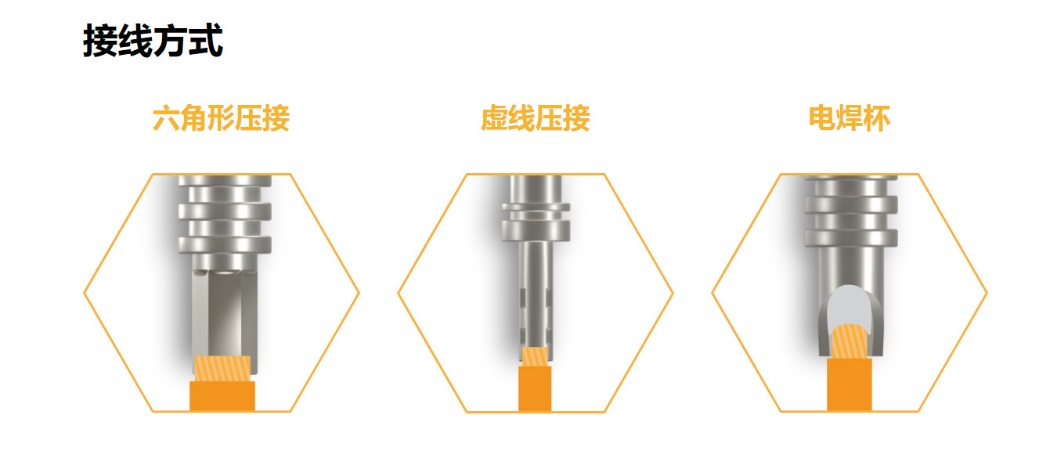

1.Solder/crimp/PCB terminal available

2.Shell material: PA66

3.Contact material: brass gold plated/Silver plated

4.Insulator: PA66

5.Temperature range:-50 ~ 150℃

6.IP50~IP protection68

Applications

U series products are mainly used in the military industry, as well as some very precise devices that require small size of connectors, such as hand-held detectors.

Samples/Structures/Detail

Note: Only a few models and their drawings are listed here, if you need more information, please go to the download center to download our product manual or contact us.

| Series: | U | ||

| IP68 waterproof,Metal circular,push pull lock, 360 degree EMC connector, High density | |||

| Shell material | Brass chrome plated | Lock style | Push pull |

| Socket material | Brass gold plated | Shell size | 00,0 |

| Pin material | Brass gold plated | Contact number | 2~13 |

| Insulator | PPS/PEEK | Termination area | AWG32~AWG16 |

| Shell color | Black, Silver | Termination style | Solder/PCB |

| Mating cycles | >5000 | Produce technology | Turned |

| Pin diameter | 0.5~2.0 mm | Coding number | 5 |

| Temperature range | ℃(-55~250) | Cable diameter | 1~6mm |

| Testing voltage | 0.5~1.6(KV) | Overmoulding available | Yes |

| Current Rated | 2~10(A) | Salt spray corrosion test | 96Hours |

| Humidity | 95% to 60℃ | Expiration date | 5 years |

| Resistance to vibration | 15g (10~2000Hz) | Guarantee period | 12 months |

| Shielding efficiency | >95db 在 10MHz | Certifications | Rohs/Reach/ISO9001/ISO13485/SGS |

| >75db 在 1GHz | Aplication | Military,testing,Equipment,handset | |

| Climatical category | 55/175/21 | Where used | Outdoor/indoor |

| Shock resistance | 6ms,100g | Customized service | Yes |

| Protection index | IP68 | Sample available | Yes |

(1) What testing equipment do you have? We take product testing very seriously. We have our own complete set of testing equipment for connectors and cables, such as: constant temperature and humidity testing machine, plug-in life testing machine, waterproof testing machine, gas leakage testing machine, negative pressure testing machine, cable swing testing machine, impedance testing machine, continuity tester, high voltage tester, ROHs tester, coating thickness tester, tensile tester, salt spray tester, etc. (2) What is the traceability of your products? Each batch of products can be traced back to suppliers, ingredient personnel, relevant production teams and testing personnel by production date and batch number, ensuring traceability of any production process. (3) Can relevant documents be provided? Yes, we can provide most documents including Certificate of Analysis/Conformance; Insurance; Certificate of Origin and other required export documents. (4) How are your products guaranteed? We guarantee our materials and workmanship, our product shelf life is 5 years, and the warranty period for quality problems is 1 year.